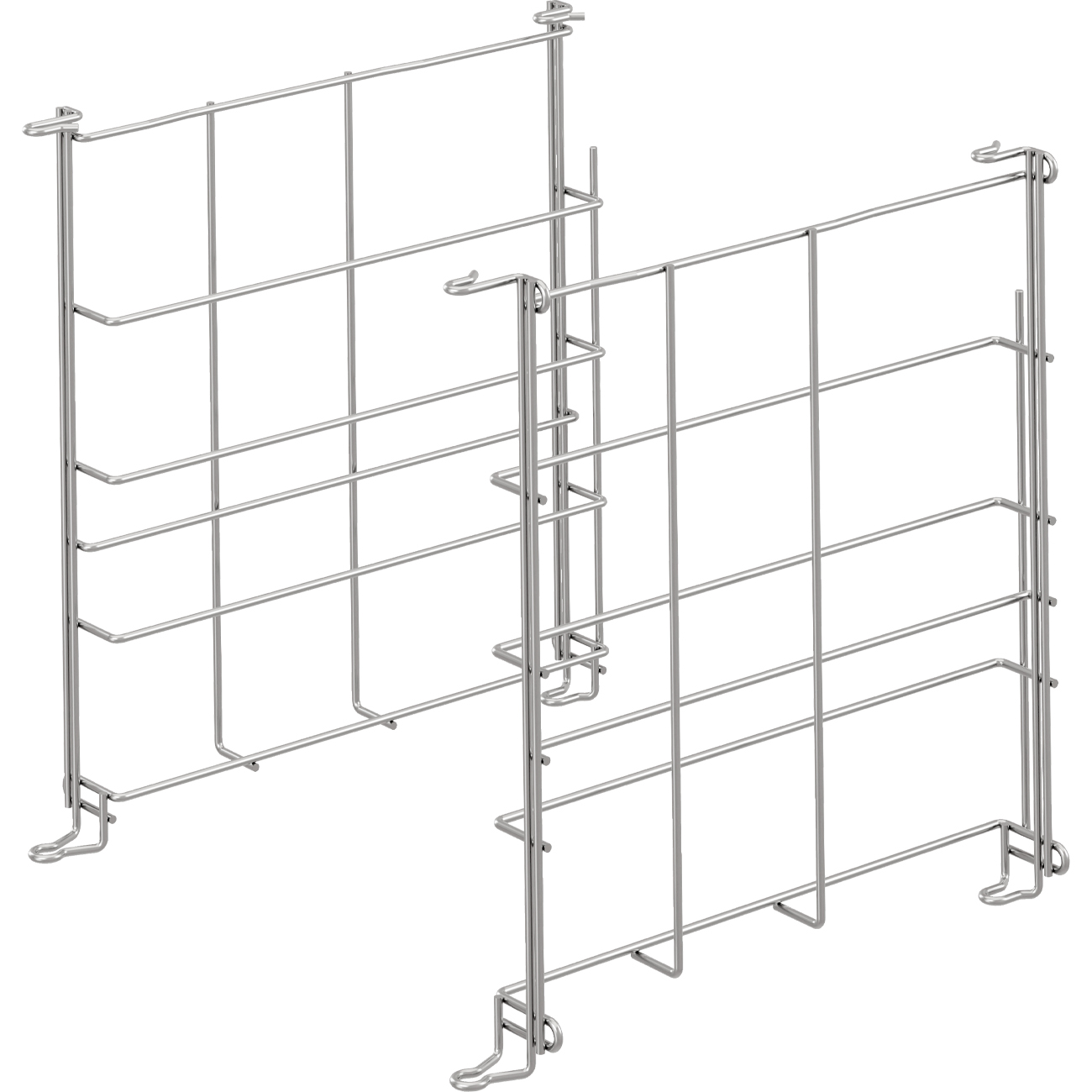

Hinged opening

Easily accessible glass for effortless maintenance and cleaning

The glass panels are designed to be easily accessible and inspectable, ensuring great convenience during cleaning and maintenance operations. This feature significantly simplifies the process, making it quick and efficient, while ensuring that every intervention can be carried out with maximum comfort and complete safety.

|

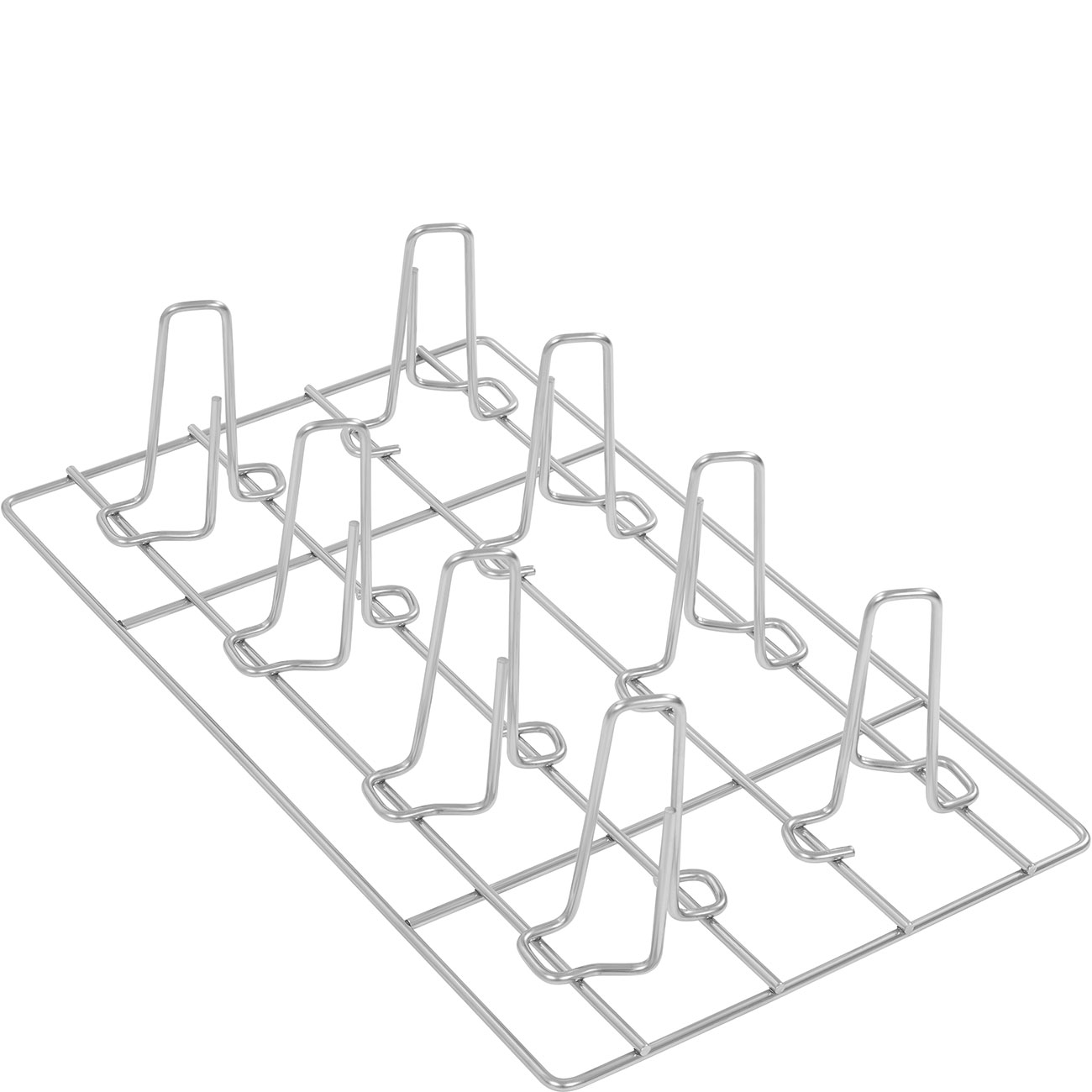

WashArt System

Efficient washing, optimised consumption, and minimal space usage

The WashArt washing system, equipped with a rotating nozzle, ensures even distribution of water and detergent within the cavity, providing deep cleaning and quick drying. To meet every need, four washing programmes are available: Short, Medium, Long, and Grill, along with a dedicated rinse programme. Thanks to its advanced technology, WashArt optimises efficiency and reduces consumption, while the rotating nozzle, with its compact design, minimises space usage in the cooking chamber.

|

Fan speed

Precise fan speed modulation for consistently even cooking results

In the Galileo Professional ovens, the fan speed can be adjusted from a minimum of 50% to a maximum of 100%, in 5% increments. This feature allows for precise customisation of the airflow, perfectly adapting it to the specific needs of each preparation. Thanks to this versatility, it is possible to achieve flawless cooking results, ensuring even and accurate heat distribution. Moreover, precisely adjusting the fan speed helps preserve the delicacy of sensitive foods, preventing exposure to excessive heat and creating the ideal conditions to maintain their lightness and internal structure.

|

Core probe

Multipoint cooking sensor for precise and uniform results

Optimal precision and control thanks to the four temperature measurement points, ensuring an accurate reading at every stage of cooking. The advanced sensor precisely detects the heat at the core of the food, guaranteeing the ideal cooking level for consistently perfect and uniform results.

|

SteamArt Technology

Open Boiler system to generate steam directly within the cavity, in quick times and at very low temperatures

Thanks to the innovative Open Boiler system, steam is generated directly within the cavity, in very short times and at very low temperatures (starting from 30°C, ideal for supporting the proofing phase). This system is particularly suited for delicate cooking processes that require the use of 100% steam, ensuring even and gentle cooking that preserves the nutritional properties, taste, and texture of the food.

|

8 cooking stages

Flexibility and precision in every cooking stage

The ability to set multiple cooking phases, in addition to preheating and keeping warm, gives the combi-steam oven exceptional versatility, responding precisely to the diverse needs of every preparation. Each phase of the cooking process can be customised with great accuracy, optimising results whether it's slow cooking at low temperatures or achieving a perfect final browning. Thanks to the advanced control of steam and heat parameters, it is possible to achieve even cooking on every surface, significantly enhancing the quality of the finished product and ensuring flawless results.

|

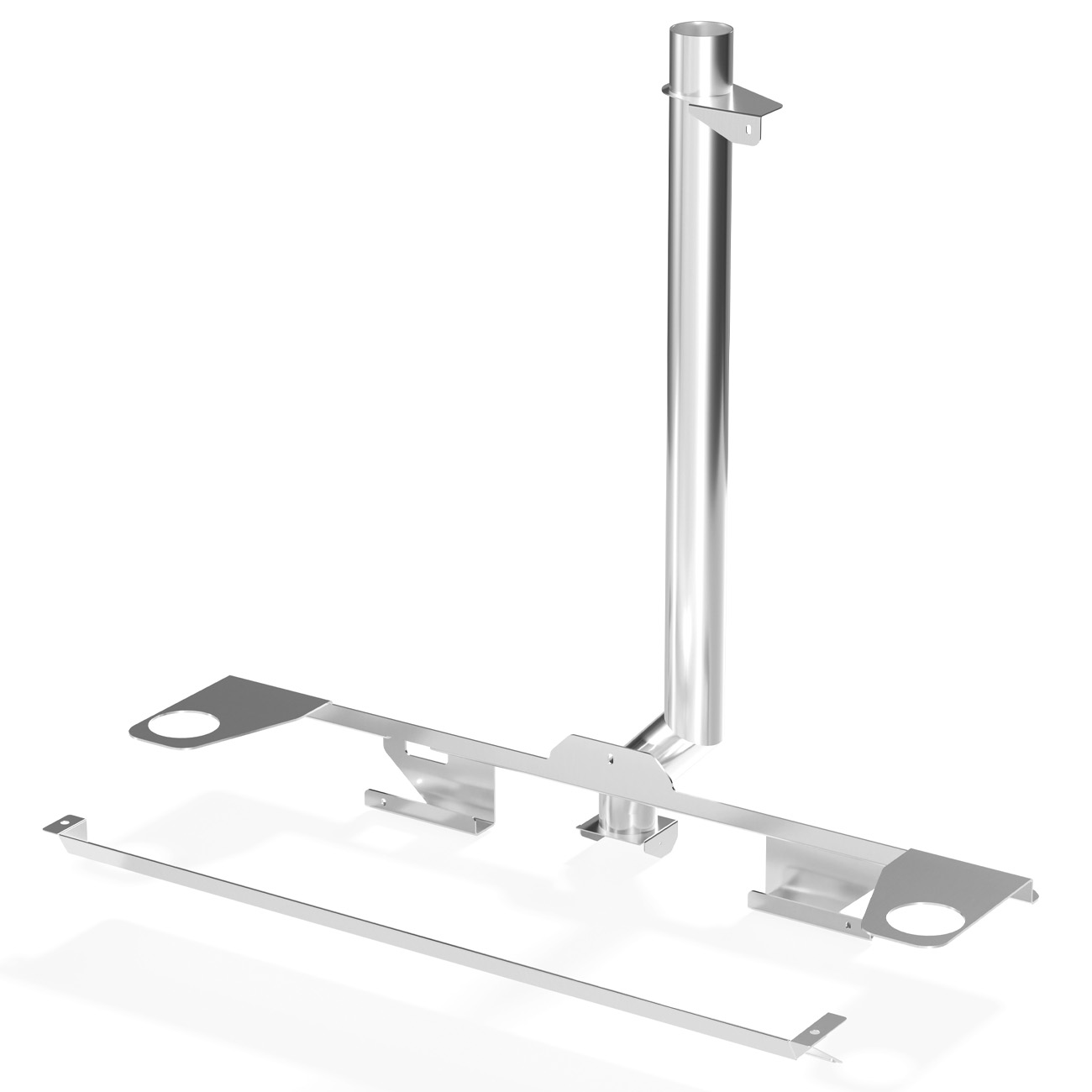

3lt retractable tank

Retractable tank with intelligent detergent level monitoring

The oven is equipped with a practical 3-litre retractable container for liquid detergent, designed to simplify and speed up cleaning operations. Thanks to this tank, up to 45 washes can be carried out before a refill is needed. The detergent level is always monitored via the "detergent level" bar displayed on the screen, which uses three intuitive colours: green to indicate a full tank, yellow for an intermediate level, and red to alert when a refill is required.

|

Waste water cooling

The temperatures are significantly lowered and the thermal impact reduced thanks to the waste water cooling system

Some ovens are equipped with a waste water cooling system that significantly lowers the temperature of the water before it is released, minimising the thermal impact. This mechanism optimises energy efficiency, enhances operational safety, and supports eco-friendly practices, helping to make the oven more sustainable and high-performing.

|